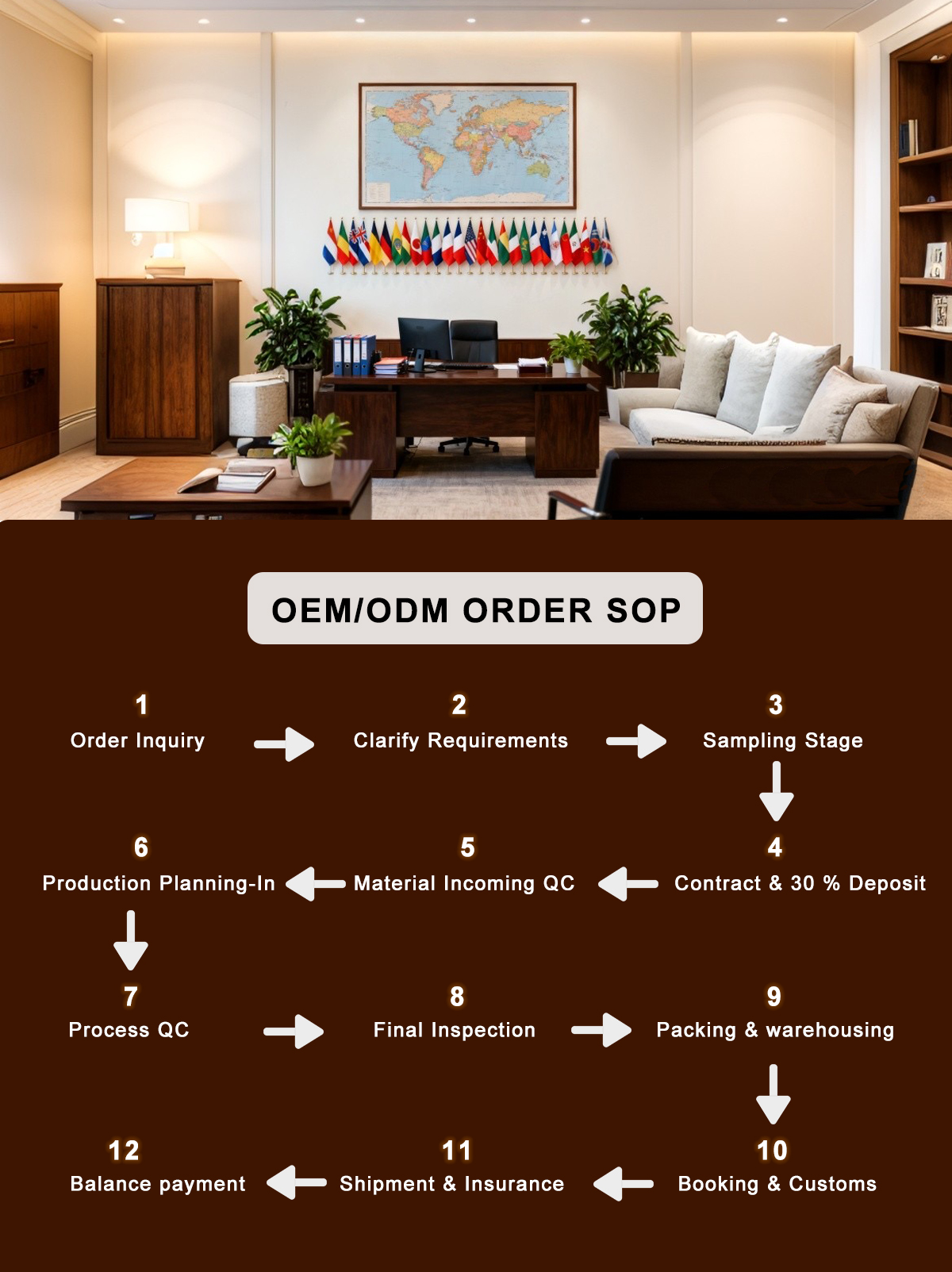

OEM/ODM Order Standard Operating Procedure (SOP)

- Market Research & Customer Development

1.1 Acquire inquiries through trade shows, B2B platforms, social media.

1.2 Verify customer as importer, brand owner or retail chain. - Requirement Clarification & RFQ

2.1 Customer fills in “OEM Requirement Sheet” (size range, LED color, logo position, packaging).

2.2 Sales send first quotation within 24 h (includes 50-1 000 pcs tier price). - Sampling Stage

3.1 Two hand-made samples ready in 7 days with spec sheet & test report.

3.2 Customer approves or requests ≤2 revisions; sign “Sample Approval Sheet”. - Contract & Deposit

4.1 Contract states ASTM F2417, CE, CPSIA, lead-time, 30 % deposit.

4.2 Project is officially kicked off after deposit received. - Supply Chain & Material Preparation

5.1 Purchase LED strip, USB charging module, water-resistant mesh.

5.2 Incoming QC ≥ AQL 1.5; reject lot if fail. - Production Planning

6.1 PMC lines 1 000 pairs/day; critical path: outsole injection → LED embed → molding.

6.2 Mass production starts only after first-article approval. - In-Process Quality Control

7.1 On-line patrol every 2 h; 100 % LED brightness & charging current test.

7.2 Record in “IPQC Patrol Form”. - Final Inspection

8.1 Sampling AQL 1.0/2.5 for function, appearance, packaging.

8.2 Issue “FQC Report”; customer may witness via live video. - Packing & Warehousing

9.1 1 pair/non-woven bag + USB cable; 12 pairs/export carton; carton mark shows PO#, barcode.

9.2 Warehouse scan-in; system locks location. - Booking & Customs

10.1 Forwarder books vessel 5 days ahead; FOB Shenzhen per INCOTERMS.

10.2 Prepare invoice, packing list, CO, CE report for ETL scan. - Shipment & Insurance

11.1 Take photos of container & seal; insure 110 % of CIF value.

11.2 Upload B/L to portal; customer receives automatic ETA alert. - Documents & Balance Payment

12.1 Send draft B/L within 2 days after on-board; customer pays 70 % balance.12.2 Release telex or express B/L; file invoice.

Your cart is currently empty.

Cart